The accuracy rates for object identification have risen as the field of computer vision has expanded with more powerful computers and sophisticated algorithms. Today’s computer vision systems are more accurate than humans at reacting to visual stimuli rapidly, achieving a 99 percent hit rate from 50 percent decades back. The global computer vision industry is on the upswing, fueled by the growing demand for hybrid and electric automobiles, increasing government funding and support for the industry, and growing demand for robotic systems guided by computer vision. By the end of this year, its total market size will be $48.6 billion.

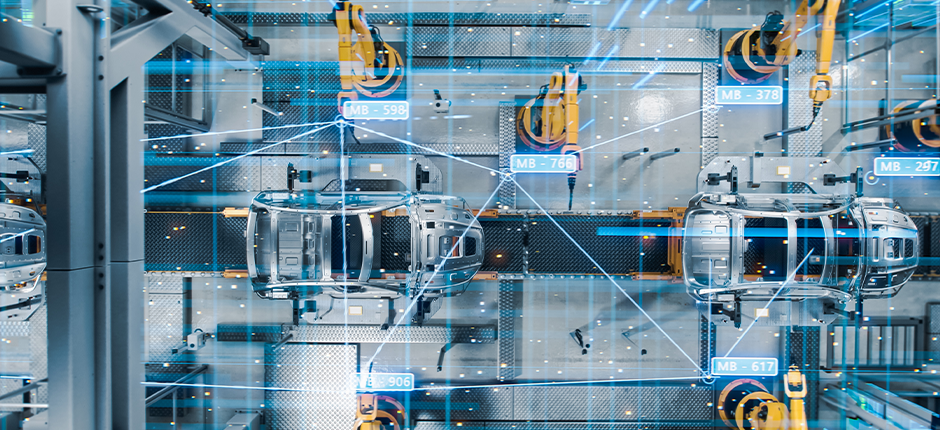

The expansion of the computer vision space has brought computer vision quality control to the fore. Few industries have benefited as immensely as manufacturing. This technology assists in automating manufacturing by allowing cameras to see and identify objects. In particular, it helps with quality control by inspecting products for defects during or after production.

Spotting Foreign Objects and Surface Imperfections During Production

Computer vision quality control is an increasingly important part of the production process. By spotting foreign objects and surface imperfections, computer vision can help to ensure that products meet the highest standards. In many cases, computer vision is more accurate than human inspection, and it can work at a faster pace.

Traditionally, quality control has been manual, with workers visually inspecting products for flaws. However, this method is often unreliable, as human error can lead to defects being overlooked. Computer vision offers a more accurate and consistent way to identify surface imperfections and foreign objects during production. By using image analysis algorithms, computer vision systems can quickly and efficiently scan products for defects. Using this information, manufacturers can adjust their production process to ensure that only top-quality products reach consumers.

In addition, computer vision quality control can help manufacturers save money by reducing the number of defective products produced. By catching issues early on, computer vision quality control can help manufacturers avoid the costs associated with recalling or repairing faulty products.

Computer Vision In-line Quality Sorting

Computer vision is particularly well suited for in-line quality sorting and can be easily integrated into existing production lines, making it a cost-effective solution for quality control. Computer vision quality control systems can be configured to sort products based on various criteria, such as size, shape, color, etc. Computer vision quality sorting has been a notable gamechanger for a widerange of manufacturers because it is:

- Cost-effective – Manufacturers devote significant human resources and funds to in-line quality control. However, leveraging computer vision technology allows manufacturers to transform quality control and, at the same time, reduce costs.

- Non-destructive – Computer vision quality control eliminates the losses incurred in handling processes during production. These losses are especially significant for perishable and delicate products.

Cognitiwe’s In-line Quality Control in Manufacturing

By integrating computer vision quality control into your manufacturing process, you can avoid costly mistakes and improve the overall quality of your product. Cognitiwe is a predictive vision AI platform that uses computer vision technologies to provide enterprises with an effective quality control process.

Cognitiwe In-Line Quality product uses computer vision to constantly monitor and evaluate data in real-time, making it an invaluable tool for preventing manufacturing flaws. The system immediately alerts the manufacturer’s team if the results don’t meet quality specifications. This way, you can detect issues even before production starts and prevent the costs of an enormous manufacturing flaw. Manufacturing companies can use Cognitiwe In-Line Quality product to create faster and more accurate forecasts about process inconsistencies, production line failures, and other abnormalities.

Adopting and running Cognitiwe does not require any AI expertise on the side of the manufacturer. It easily adapts to your existing infrastructure, including the IP cameras standard in manufacturing plants. On-premises inspection is entirely autonomous, and results are presented in real-time on Cognitiwe’s graphical user interface.

Contact us today, and let’s see how Cognitiwe can help you leverage computer vision for in-line quality control at your production facilities.